Introduction: Conduct Life Cycle Impact Assessment

In a Life Cycle Assessment, a Life Cycle Inventory is used to assemble and record the emissions and resources used that may be linked to a particular product. Then an impact analysis is carried out, taking into account issues relating to the use of natural resources, human health, and the environment. Climate change, ozone depletion, eutrophication, acidification, human toxicity (cancer and non-cancer related), respiratory inorganics, ionizing radiation, Ecotoxicity, photochemical ozone formation, land use, and resource depletion are among the effects taken into account in a life cycle impact assessment. Each of these impact categories is given a set of emissions and resource allocations. Then, utilizing impact assessment techniques, they are transformed into indicators. Then, the effect indicators can be cross-compared between various emissions, resource consumption, and product options.

Table of Contents

- Introduction: Conduct Life Cycle Impact Assessment

- Life Cycle Inventory Analysis (LCI) And Life Cycle Impact Assessment (LCIA)

- Meaning of Life Cycle Impact Assessment

- Purposes of Conduct Life Cycle Impact Assessment

- Important features of Life Cycle Impact Assessment

- Reasons Why The LCIA Needs To Be Divided Into Different Components

- LCIA Mandatory Requirements are:

- How Non-Assessment Can Affect The Environment

- Benefits of LCA on Policy

- How it is Important

- Conclusion

--------------Blog Contact Form-------------

Life Cycle Inventory Analysis (LCI) And Life Cycle Impact Assessment (LCIA)

Life Cycle Impact Assessment, or LCIA, is the third stage of the life cycle assessment process (LCIA). LCIA was created to help people comprehend the environmental significance of a product system's Life Cycle Inventory analysis (LCI) findings. To summarize and explain the LCI findings, the LCIA phase replicates specific environmental issues, known as impact categories, and uses category indicators. LCIA can be used, for example, as a component of an overall LCA to pinpoint possibilities for system and product improvement and assist in prioritizing which products should be chosen above others.

Although LCIA can assist with these uses of plastic items, you should be aware that a complete assessment of a plastic product is a time-consuming procedure and may call for the use of a variety of different environmental assessment techniques.

- The environment is being greatly harmed by plastic products, and the additional harm that comes from its non-assessment makes the environment even worse than it already is.

- During the production stage, the looping method is crucial for reducing the environmental impacts of polypropylene and PP-PE-PET mixed plastic goods.

- The life cycle evaluation approach, which was created from the extraction and manufacture of raw materials, is used to transport mixed and homogeneous plastic products.

- The utilization of energy and material resources, emissions, and environmental impact indicators are the main points of interest.

We will talk about the environmental impact of various production steps.

For instance,

- Using process water and plastic waste during the production stage.

- The looping technique involves recirculating wastewater and plastic scrap.

- Wastewater is treated in a municipal wastewater treatment plant after plastic scrap is burned in an incinerator process.

- Wastewater is cleaned while plastic debris is disposed of in a municipal dump.

Meaning of Life Cycle Impact Assessment

The life cycle impact assessment is a method for evaluating how different products will affect the environment from the time that raw materials are produced until the end of their useful lives.

The various production steps allow for the life cycle assessment to be done. Finding the objective and the limits is the first step in the LCA process. At all stages of the life cycle, the chance to design solutions to reduce environmental effects should be thankful for the creation of various software programs and built databases.

- The investigation of a polymer product's environmental impact can be done most effectively through the life cycle assessment.

- The carbon footprint for the various stages of transportation and waste management operations can be calculated using the life cycle assessment methodology.

- The physicochemical characteristics, processing circumstances, and waste purity of the recovered polymer product all affect its quality.

- By restricting the extensive application of such chemical processes, the researchers have made an effort to address the economic and ecological effects.

- The life cycle analysis is used in the production process to promote environmentally sustainable products while keeping the product's effectiveness and value unaltered via the looping approach.

- The use of renewable production methods has expanded along with the manufacture of plastic, which has decreased the amount of garbage produced as a result. Within the new framework of sustainable production, plastic scrap looping has the potential to be useful in the production stage.

- Although the production stage life cycle evaluation has a significant impact on environmental performance.

The usage of recycled trash, as opposed to raw material, has many advantages. It has not yet been done to analyze the life cycle of plastic items using process water looping and scrap. Here, the main premise is being put into practice through the reduction of raw material, energy, and waste generated during production, with an emphasis on re-use aiming for proper product re-use.

Application of the life cycle assessment follows ISO 14040 and 14044 standards. The categories of environmental effects are established throughout the life cycle impact assessment phase. The evaluation of the environmental impact of the production process over the whole life cycle of the plastic product, from raw material extraction to the end product and plastic trash.

Read Our Blog: Life Cycle Assessment of Products as Per ISO 14040

The homogeneous polypropylene and PP-PE-PET granules are manufactured in the European Union and put through processing at the nearby polymer injection molding facility. The plastic trash is handled as plastic waste in an incinerator or in a landfill after the granules are molded.

The looping approach is used to investigate the injection molding procedure, and it involves recycling plastic waste while managing 50% of the cooling water as wastewater.

The impact evaluation establishes the production process without looping; wastewater is handled in a municipal wastewater treatment facility and plastic trash is burned.

The third scenario assesses the effects of landfilling plastic trash and wastewater treatment on resources and the environment.

Read Our Blog: Waste Water Treatment

STANDARD ISO 14042:2000 (E):

(Life Cycle Impact Assessment) Life Cycle Analysis, Environmental Management, and Life Cycle Impact Analysis

This International Standard outlines the main characteristics and inherent constraints of the Life Cycle Impact Assessment (LCIA) phase of Life Cycle Assessment (LCA) as well as provides guidelines on a general framework for LCIA. It details the LCIA phase's requirements as well as how it relates to the other LCA stages.

The potential environmental impact that is referred to in ISO 14040, the full expression of this term is “life cycle impact category indicator”, this is a subset of the “environmental impacts” referred to in ISO 14001 resulting from the use of the functional unit calculation. While being involved in the process, the functional unit of Plastic products is referred to as “Potential environmental impacts”.

Definitions of Keywords: ISO 14001, ISO 14040, ISO 14041, and ISO 14050 are applicable for the purposes of this International Standard.

The life cycle inventory analysis result is the output of a life cycle inventory analysis that takes into account flows that cross system boundary and serves as the foundation for Life Cycle Impact Assessment.

Impact category class denoting significant environmental problems that LCI outcomes may be related to Life Cycle Impact category indicator

Characterization factor: The evaluation of the factor derived from a characterization model is applied to convert the assigned LCI results to the common unit of the category indicator.

Purposes of Conduct Life Cycle Impact Assessment

Life Cycle Impact Assessment (LCIA) aims to examine the product (Plastic) from an environmental standpoint using impact categories and category indicators connected with the Life Cycle Impact results. The LCIA phase also provides information relating to the life cycle interpretation phase.

Important features of Life Cycle Impact Assessment

Key features of the LCIA are listed below:

- The LCIA phase offers a system-wide perspective on environmental and resource issues for one or more product systems, in conjunction with other LCA phases (s).

- Impact categories are assigned to LCI results by LCIA. The category indicator result, also known as the indicator result, is calculated for each effect category after the category indicator has been chosen. The LCIA profile - a grouping of indicator results - provides details on the environmental problems connected to the inputs and outputs of the product system.

- LCIA is a comparative approach and is based on a functional unit; it differs from other techniques including environmental performance evaluation, environmental impact assessment, and risk assessment. Information obtained by these various methods may be used by LCIA.

The LCIA phase's overall structure is made up of a number of necessary components that translate LCI results into indicator outcomes. Additionally, there are optional components for approaches for data quality analysis as well as for normalizing, aggregating, or weighting the indicator results.

Reasons Why The LCIA Needs To Be Divided Into Different Components

- Each LCIA component is different and easily recognizable.

- Each LCIA component should be taken into account separately during the aim and scope determination stage of an LCA research for getting clarified results.

- For each LCIA element, a quality assessment of the LCIA methodologies, assumptions, and other choices can be made.

- Each element's LCIA practices, presumptions, and other operations can be made transparent for unbiased assessment and reporting.

- Each element's usage of values and subjectivity, also known as value choices, can be made transparent for critical examination and reporting.

LCIA Mandatory Requirements are:

- The impact categories, category indicators, and characterization models that will be used in the LCA research would be different as per the requirement. The impact categories, associated category indicators, characterization models, category endpoints, and related LCI results are also identified. As if using infrared radioactive forcing as the category, the climate change impact category indicates emissions of greenhouse gasses (LCI findings).

- The categorizing of LCI results in impact categories

- Results of category indicator calculation (characterization).

Requirements along with Assessment while keeping in mind the objective of LCA are:

- Determining the size of category indicator findings in relation to reference data (normalization).

- Grouping entails classifying and conceivably ranking the impact categories.

- Weighting: applying numerical factors based on value-based choices to convert and maybe aggregate indicator data across effect categories.

- Data quality analysis: a better knowledge of the validity of the LCIA profile and the outcomes of the indicator results collecting.

LCIA phase’s for collection of indicator results for the various impact categories:

The relationship between the LCI results, category indicators, and in some cases category endpoint, characterization models reflect the environmental mechanism(s). The characterization factors are derived using the characterization model. Each impact category's essential elements are as follows:

- The definition of the category indicator for the specified category endpoint(s)

- The selection of the category indicator and the identified category endpoint(s)

- The identification of appropriate LCI results that can be assigned to the impact category

- The identification of the characterization model and the characterization factors.

- This process makes it easier to gather, assign, and characterize data from appropriate LCI models. This also aids in highlighting the characterization model's level of correctness and scientific and technological validity, assumptions, and value judgments.

- The sum of all environmental processes that are connected to climate change is known as the environmental mechanism.

- Intergovernmental Panel on Climate Change provides Guidance and Requirements for the selection of impact categories, category indicators, and characterization models including the criteria for environmental relevance.

- Whenever impact categories, category indicators, and characterization models are selected in an LCA, the related information shall be referred to.

- When new impact categories, category indicators, or characterization models are defined, the requirements and recommendations will apply.

- The category indicator can be chosen anywhere along the environmental mechanism between the LCI results and the category endpoint(s).

The requirement of impact categories, category indicators, and characteristics models:

- The impact categories selection, category indicators, and character models shall be going on with the aim of LCA.

- The impact category source, category indicators, etc, shall be referenced for this purpose.

- These categories shall be justified and accurate and descriptive names shall be provided for the category indicators, which must be justified.

- The impact category and category indicators shall be accurate and descriptive.

- The impact categories shall reflect comprehensive environmental issues related to the product (Plastic) the goal and scope will also be considered.

- The appropriate category model used for the category indicator must be described.

The recommended selection for the impact category, category indicators, and characteristics models are:

- The impact category, category indicators, and characteristics models must be internationally accepted, as per the international agreement, and approved by the relevant international organizations.

- The impact category should be the aggregate emissions or resource use of the product (Plastic product) at the category endpoint through the category level indicators;

- The value choices and assumptions made during the selection of impact categories, category indicators, and characteristics models should be minimum.

- The impact category, category indicators, and characteristics model should not be double counted.

- All these categories should be scientifically and technically valid and must be based on a distinct identifiable environmental mechanism and reproducible empirical observation.

- The characterization model and indicators should be identified up to the extent it is valid.

- The indicators should be relevant environmentally.

The environmental mechanism, goal, and scope, spatial and temporal differentiation of the characterization relating to LCI results must be considered as per the category indicator.

The LCI other than mass and flow of data included in the LCA, such as land use, shall be identified and their indicators should be determined.

The environmental relevance of the data is:

- The category indicator as per the consequence of the LCI results on the category endpoint, qualitative indicators.

- The additional environmental data to the character model with respect to category endpoint includes

- Reasons for the category endpoints.

- The magnitude of assessed changes in the category endpoints.

- The spatial aspects, such as area, scale,

- The temporal aspects, like duration, residence time, persistence, timing, etc.

- The environment mechanism reversibility, and

- Uncertainty of the linkages between the character model and the changes in the category endpoint.

How Non-Assessment Can Affect The Environment

A product system's unit processes can be characterized or benchmarked over time, relative comparisons between product systems based on chosen category indicators, and the identification of environmental issues for which other techniques can provide complementary environmental data and information useful to decision-makers can all be done using LCIA as part of an overall LCA.

Although LCIA can help with these applications, parties should be aware that a thorough evaluation of a product system is challenging and can be needed for the employment of a number of different environmental assessment methods.

Benefits of LCA on Policy

Making Choices

- The proper balance of economic, social, and environmental factors

- Not based on emotion or a gut instinct, but rather on evidence from science.

- Having standards and the capacity to distinguish between good and poor things (for humans and the environment)

Management:

- Management of the life cycle (raw materials, production, usage, disposal, and recycling), and Recycling.

Economic Action/taxes

- Non-tariff obstacle (NTB) • Competitively

- Environmental taxes (costs to society outside of the environment)

- Subsidization, such as for recycled materials, biofuels, or bio plastics?

- Encourage, support, and promote investment (BOI)

How it is Important

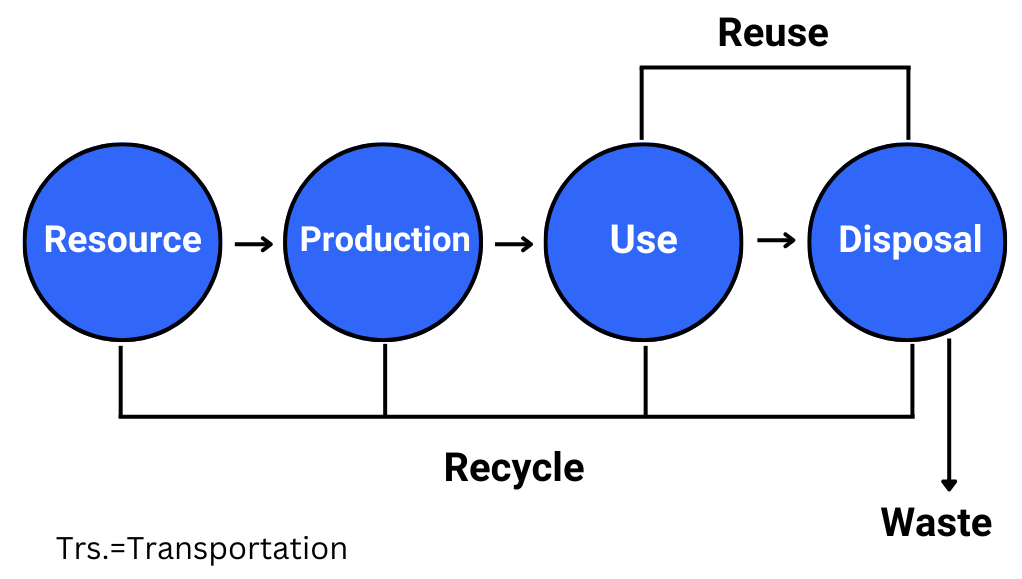

Life cycle impact assessment is a tool to assess the potential environmental impacts of product systems or services at all stages in their life cycle- from the extraction of resources through the production and use of products to reuse, recycling, and final disposal.

The various stages is being defined through the different stages via a diagram:

The third stage of life cycle assessment is referred to in ISO 14040 as life cycle impact assessment or LCIA. In order to better grasp the environmental importance of a product system's life cycle inventory analysis (LCI) findings, LCIA was developed. The LCIA phase simulates certain environmental problems, referred to as impact categories, and employs category indicators to summarize and interpret the LCI findings. Indicators for each effect category are meant to represent the total emissions or resource utilization. Those "possible environmental consequences" that are mentioned in ISO 14040 are represented by these category indicators. LCIA also gets ready for the phase of life cycle interpretation.

The main focus of the Life Cycle Impact Assessment's total inputs and outputs is on characterization techniques; all studies used the same normalization and weighting techniques. Global warming, eutrophication, acidification, photochemical ozone formation, human toxicity, abiotic depletion (fossils and elements), and marine aquatic Eco toxicity are eight environmental consequences that are covered in this article. With the exception of biogenic carbon, the potential value of global warming is for 100 years. Potentials for eutrophication and acidification are intimately correlated with sulfur, nitrogen oxides, and phosphorous compounds.

The possibility of photochemical ozone synthesis was taken into account when analyzing the development of tropospheric ozone. The impacts of poisonous compounds are referred to as human toxicity potential.

Conclusion

The consumption patterns of humans have changed significantly, and there is a growing market for plastic waste. The choice of material for plastic-containing and biodegradable Plastic Waste has grown to be a crucial but unresolved issue. This report clarified two important issues about the material flow and life cycle environmental effect assessment of various Plastic Waste based on first-hand field investigation.

The Life Cycle Assessment (LCA) takes into account the energy needs for upstream processing (feedstock energy) of raw materials, processing energy of the product made from the materials, energy for use of products where transport energy is combined, and energy for disposal or recycling/composting/incineration/landfilling at the end of the life.

The life cycle scenarios' greenhouse gas emissions into a single footprint. The methodology for calculating the life cycle assessment (LCA) study of the product is based on the idea of total CO2 equivalent for manufacturing the product in a boundary system (cumulative energy in the boundary system in terms of CO2 equivalent + cumulative greenhouse gas emitted in terms of CO2 equivalent) that has the potential to cause global warming.

This portion of the site is for informational purposes only. The content is not legal advice. The statements and opinions are the expression of author, not corpseed, and have not been evaluated by corpseed for accuracy, completeness, or changes in the law.

BOOK A FREE CONSULTATION

Get help from an experienced legal adviser. Schedule your consultation at a time that works for you and it's absolutely FREE.

.webp)

.webp)